Shipment will be arranged after all previous payment phases have been finished, however please note that depending on the circumstances some shipment terms (eg. FOB, FCA) may not be applicable. For instance, if the customer has designated a third party to pick up the shipment from our warehouse and then to load the goods, we would be unable to specify this as FOB since we were not involved in the onboarding process. To avoid any of these shipment terms conflicting, please specify your delivery needs and other specifications during the initial quotation phase.

If FOB is utilized, we will provide the following documents:

-

Commercial Invoice

-

Packing List

-

Bill of Lading (B/L)

-

Export License/Permits

-

Certificate of Origin (COO)

-

Dock Receipt/Mate’s Receipt

-

Pre-Shipment Inspection Report (if required)

If FCA is utilized, we will provide the following documents:

-

Commercial Invoice

-

Packing List

-

Transport Document

-

CMR Consignment Note

-

Air Waybill

-

Rail Consignment Note

-

Export License/Permits

-

Certificate of Origin

-

Forwarder’s Cargo Receipt (FCR)

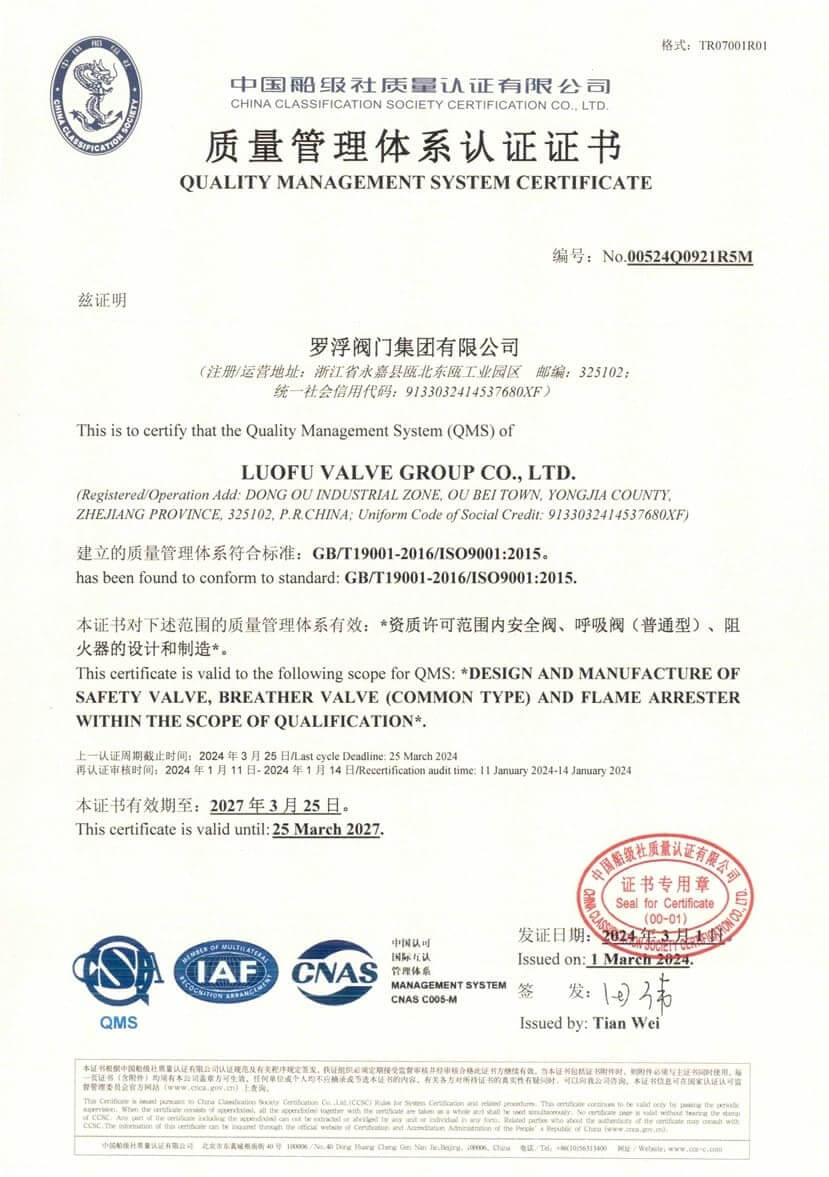

IS09001: 2015

IS09001: 2015

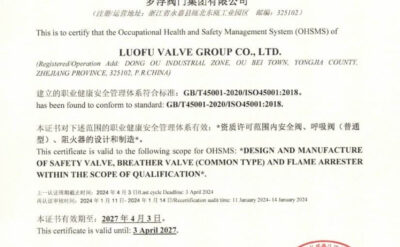

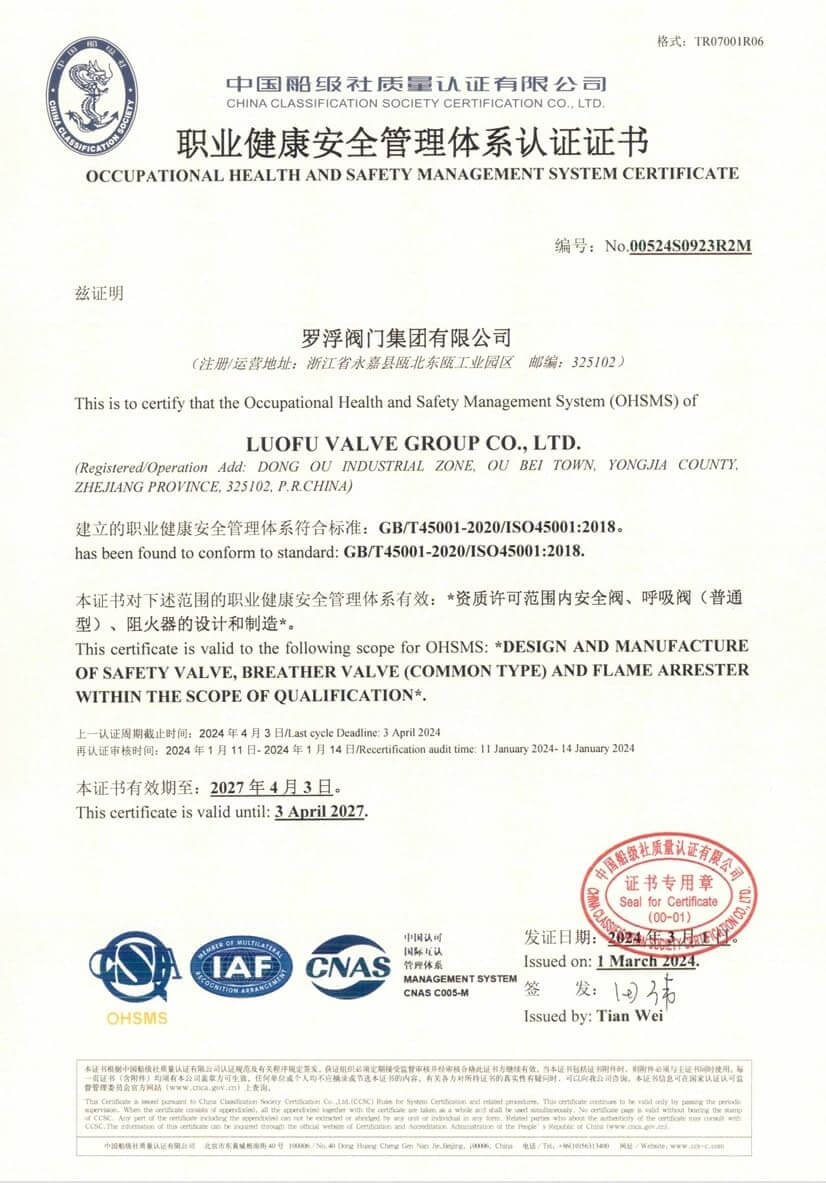

IS045001: 2018

IS045001: 2018

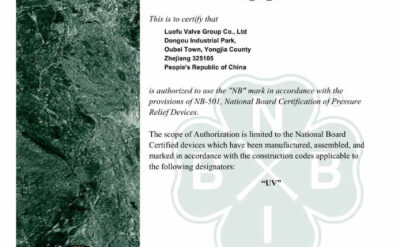

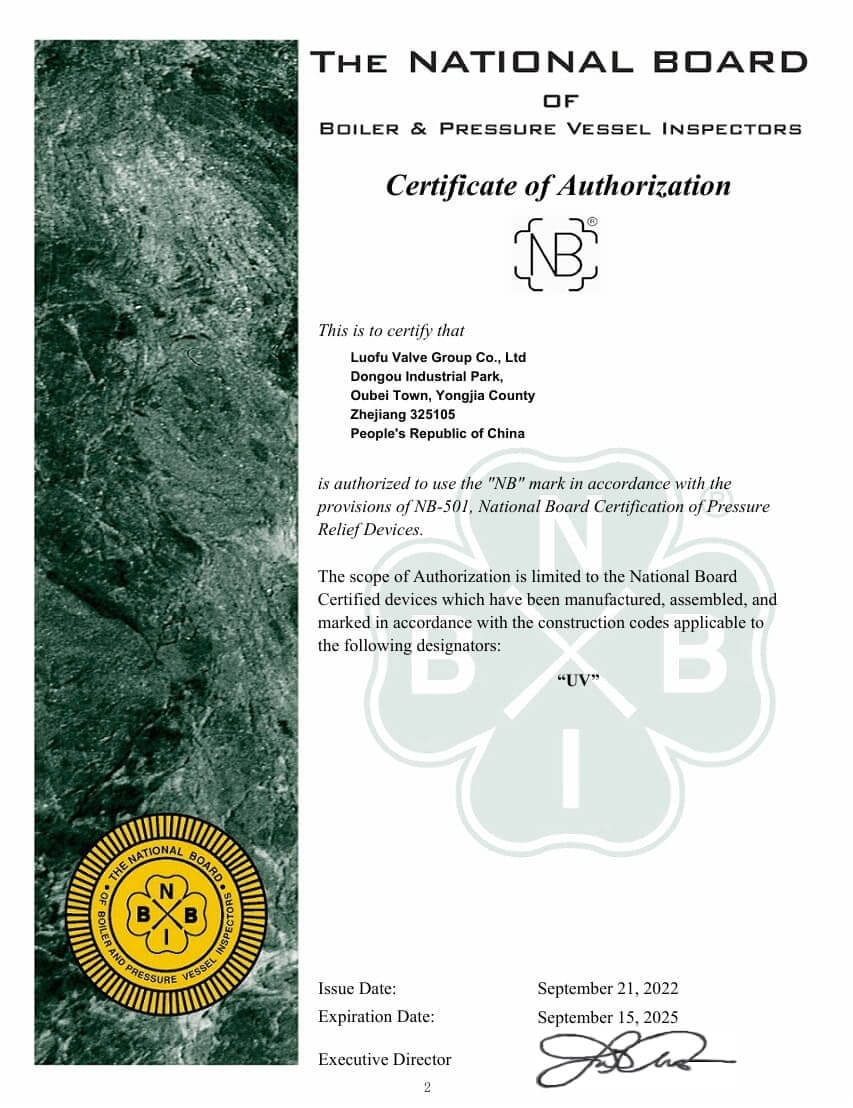

NBBI

NBBI

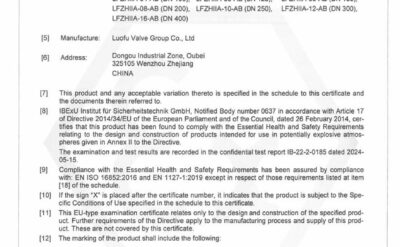

IBExU

IBExU

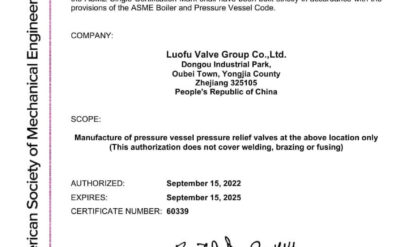

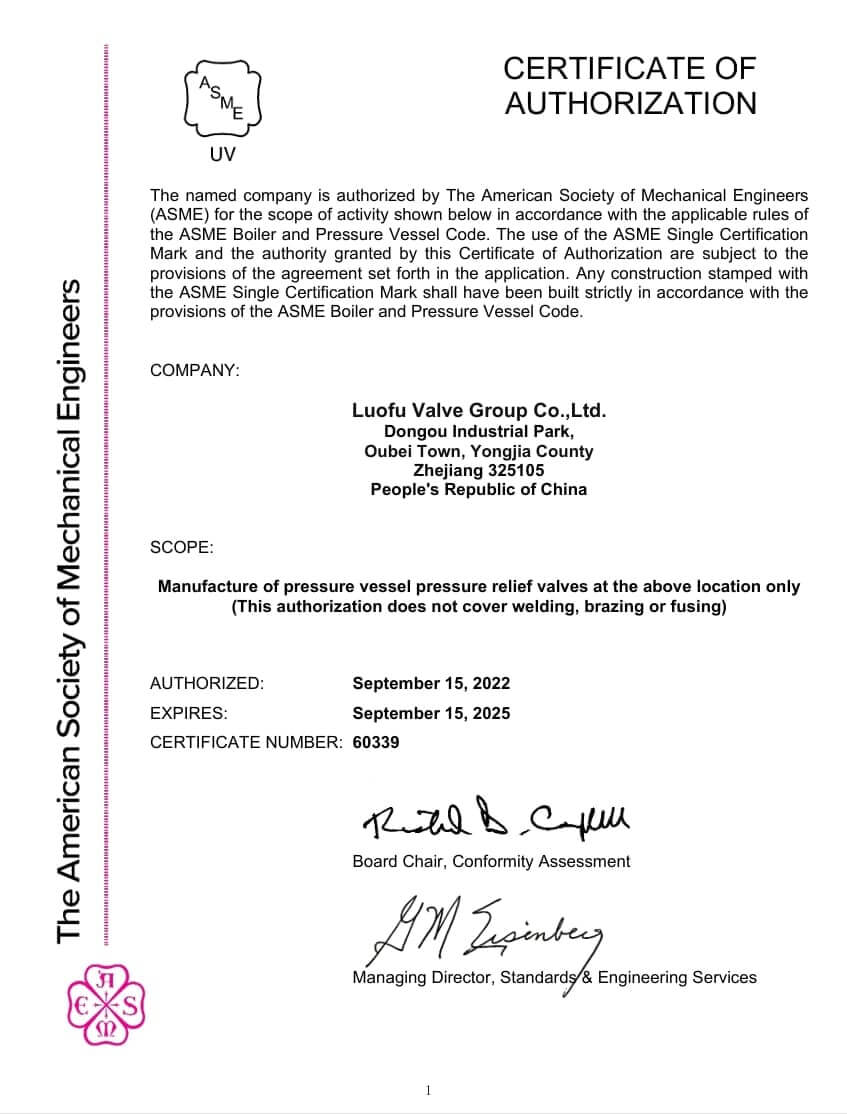

ASME UV

ASME UV

Reviews

As a petrochemical product manufacturer, CNOOC Oil & Gas (Taizhou) Petrochemical Co., Ltd. is committed to ensuring the continuity and stability of production and operation of each unit. In order to ensure the annual production target, under the correct leadership of our company's leaders, all staff have carefully organized and worked hard. The company's production work is being carried out in an orderly manner according to the plan, and the four major controls are fully controllable. Your company made outstanding contributions to us in the supply in the fourth quarter of 2017, which reflects the good strategic partnership between your company and CNOOC Oil & Gas (Taizhou) Petrochemical Co., Ltd. Here, we would like to express our sincere gratitude to the leaders and relevant staff of your company for their strong support.

CNOOC Oil & Gas (Taizhou) Petrochemical Co., Ltd.

Luofu is trustworthy in terms of product quality, price, delivery time and after-sales service.

PetroChina Guangxi Petrochemical Company

Our company is the EPC contractor of 476 system unit safety valves for the ZhongKe (Guangdong) Refinery & Petrochemical Company limited Refining and Chemical Integration Project. We use the safety valve products of Luofu Valve Group Co., Ltd. After quality inspection, they are stable and run well.

Sinopec Luoyang Engineering Co., Ltd.

Thank you Luofu Valve for your cooperation all the time! You have given us all-round support in safety valve technology selection and pre-sales service.

Moon Environment Technology Co., Ltd.

As an OEM supplier, your company always puts product quality and innovation at the top of the enterprise development, which is impressive. The Safety Valve and Changeover Valve Lockable Combination used on our company's compressors are of reliable quality and timely delivery!

ShenGu Group